Computer-Aided Design (CAD) has been one of the most enduring and adaptable aspects of computers in the workforce. The first use of a CAD program goes back to 1962 and SketchPad, a program that lets users draw directly on a screen for the first time.

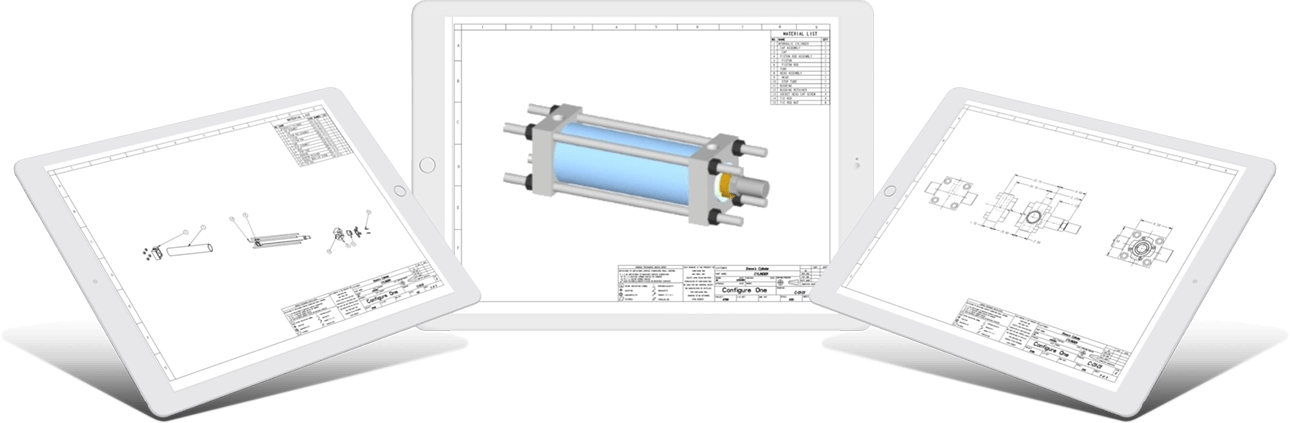

To give you a better understanding of CAD and how it can integrate into your CPQ system to provide a remarkable customer experience, we’ll take a look at what CAD automation looks like in a manufacturing setting, why it has become so important, and what the future of CAD automation looks like.

Products

Resources

Our Offices

9000 Cypress Green Dr.

Suite 255,

Jacksonville, FL 32256

United States

[email protected]